THE CLEANLEAD PROJECT: “DEVELOPING A NEW CONCEPT ‘CLEANLEAD’ FACTORY FOR EUROPE”

A Pproject

partially founded by the European Union within the “GROWTH

PROGRAMME”. This three

year Pproject had a duration of

three years, and it has been was successfully completed in accomplished

on April 2004.

PROJECT PARTNERS INVOLVED

Técnicas Reunidas S.A. (ES), Britannia Refined Metals Ltd (UK), Orzel

Bialy S.A. (PL), Instytut Metali Niezelaznych (PL), Coventry University (UK),

Lafarge Plasterboard Ltd (UK), Faculdade de Ciéncias da Universidade de Lisboa

(P), Netherlands Organisation for Applied Scientific Research (NL), Magneto

Special Anodes B.V. (NL), Membraan Applicatie Centrum Twente (NL), Kovohute Prĭbram

A.S. (CZ), Institute for Nonferrous and Rare Metals (RO)

OBJECTIVES

Secondary lead consumption is certain bound to

raise due to an ever

increasing demand

for lead acid batteries for the demand for automotive

industry, and also related to new uses

such as the electric vehicles andor

hybrid vehicles, solar and renewable energy storage and,

portable and auxiliary batteries in emergency systems, etc.

The lead battery recycling industry currently faces the challenge of

improving the conventional processes

aiming to avoid toxic wastes generation (slags, mattes, etc) generation

and trying to complying with the

more stricter environmental regulations.

The CLEANLEAD pProcess

provides a new, low energy

cost, zero-waste generation sustainable option which

can substantially improve substantially the

current lead smelting operations. The new process has been developed to deal

efficiently with the whole batteriesy

components, includinge.g.

drained acid treatment, optimisation of the smelting stage and

hydrometallurgical treatment of the battery pastes.

Cleanlead Process Conceptual Diagram

DRAINED ACID TREATMENT

The CLEANLEAD Process for drained acid treatment not only prevents the

current production

of sludge for disposal from being produced, but also turns

the acid into reusable products. Depending on the applied process option,

commercial synthetic gypsum, or acid for new batteries may be produced refilling

or biotreatment may be used on theof

effluents can be performed. This wide range of purposes

options

makes the described technology applicable

suitable

for to many different cases applications and

industrial problems.

Commercial Gypsum Production

Detail of the gypsum product

Current processes turn the drained acid containing metallic impurities

into a waste sludge for disposal by adding lime or sodium hydroxide. This treatment has severeimplies

associated environmental costs. The CLEANLEAD Process makes commercial synthetic

gypsum through drained acid purification by means of membrane techniques such

as diffusion dialysis and nanofiltration or chemical precipitation prior to lime

addition. The CLEANLEAD synthetic gypsum fits complies with the

specifications to be used asfor feed

material in the

plasterboard industry, as an additive in the cement industry and also in

floorscreeds manufacturing since the process can be

conducted

adjusted

to get different gypsum products. Besides environmental advantages,

producing commercial gypsum versus in place of an acid sludge is economically

attractive.

Obtaining reusable battery acid

presents attractive economic revenue.

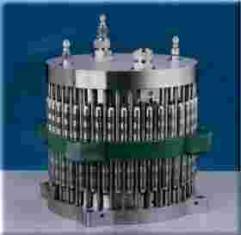

Membrane Electrolysis cell

The Ddeveloped

electrochemical process allows obtaining can produce a clean

and concentrated sulphuric acid (30% w/w) suitable for filling new

batteries refilling through . This is achieved

with electrodialysis technology, yielding efficient removal of the

metallic impurities.

Biological treatment

The CLEANLEAD Process also provides

includes biotreatment

of drained acid blended with other industrial alkaline effluents (landfill

leachates, etc) by means of biologically produced H2S to remove the impurities and yield getting

finally a non non-polluting final productstream.

OPTIMISED SMELTING OPERATIONS

Improved Operation

Rotary Furnace

Desulphurised battery paste smelting methods were developed within the

CLEANLEAD project as an alternative to conventional raw paste smelting. Very positive

results have been obtained in trials performed in a 500 kg rotary furnace,

which are summarised as follows:

• Ddecreaseding

smelting temperature up down to 900 ºC

• 3-4 times shorter smelting time

• Sslag

amount reduction by 65-75%

• Sstable

silica slag type being produced

• Rreducedtion consumption of

fluxes and reductants consumption

• Llead

bullion yield up to 75% of the charge mass

• Ddusts

volume reduction and low SO2 emission

Producing Stable Slag

Electric Furnace Isasmelt Furnace

Further achievements on preventing unstable slag from being produced are

available within the CLEANLEAD technology. Conventional unstable sodium-based slag can be re-smelted in an electric arc furnace. Tests carried out in

a 80 kVA pilot unit confirm that re-smelting

of soda slag in the presence of iron oxides and sand produces non-toxic stable

ferrosilicate slag. In addition, some matte is generated, which reduces SO2 emissions.

Another way developed process uses deals

with using the sodium sulphate slag from an Isasmelt furnace as

flux in athe

rotary furnace. In

tests Tthis slag performed as well as the currently

used sodium carbonate flux and therefore can replace it, thus reducing the operating cost.

Benefits

The technological innovations described above have been integrated in the CLEANLEAD

optimised smelting process, which providespresents

great flexibility and important

improvements to suit local operating requirements. The gathered

benefits of the optimised smelting processes are:

·

ØStable

ferrosilicate slag is

produced complying withwithin current and future

environmental regulations is produced, avoiding the current

generation of unstable and toxic sodium-based slag.

·

ØElimination

or substantial reduction of SO2 gas emission.

·

ØDecreaseding

energy consumption and total operating

costs.

·

Ø Improveding process performance and environmental aspects

impact

of furnace operations.

HYDROMETALLURGICAL TREATMENTy

A Novel

Process as an Advantegous

Optiona

Preferred Alternative

to Smelting

Lead Electrowinning Pilot Cell

A novel process under in the CLEANLEAD

technology deals with the hydrometallurgical treatment of battery paste to

obtain pure Pb. This approach stands as is an

advantageous

superior alternative option

to smelting and offers zero waste and low cost sustainable

technology.

An Eco-efficient and Low Cost Technology

In this process, battery paste is reduced and desulphurised to render it

suitable for feeding a low energy lead electrolytic process. Reduction is

carried out by adding drained battery drained

acid together with a small amount of lead bearing sulphides such as mattes, concentrates,

fumes, etc., as reducing agents, which givesinvolve

lower costs and an extra amount of improved lead recovery

eventually recovered. The desulphurisation is performed with

sodium hydroxide, which is regenerated in a subsequent step. This saves consumable

the cost of consumables

and produces valuable gypsum. Desulphurised paste is leached with sodium

hydroxide at 60 ºC, and then the pregnant solution containing dissolved lead

passes to lead electrowinning in alkaline media, having an energy requirement

of 0.5 kWh/kg Pb and current efficiencies close to 100%. The developed

electrolytic process shows important technical and environmental advantages,

and offers present

lower operating costs than conventional lead smelting technology.

Vesatility of

Products

As an alternative to lead electrowinning, the CLEANLEAD pProcess

also allows pure Lead Oxide production at very competitive cost, which is

suitable for new pastes the manufacturing

of new pastes or other industrial applications.

The CLEANLEAD Process represents a radical innovation and definitive

solution to the current problems the secondary lead

industry is presently facing in Europe and worldwide.

The new technologies deal efficiently with all battery components, e.g.

drained acid, metallic lead, and pastes, proposing providing the

best solution infor

every case.

Sustainability is a must for is fundamental to the

developed CLEANLEAD process, by pursuing zero-waste emissions, getting

obtaining

substantial savings in operating and environmental costs, and producing

reusable valuable products instead of toxic wastes or slags generated by

conventional smelting processes.

High quality and diversified products can be obtained, such as pure lead

oxide, pure electrolytic lead, commercial gypsum, etc.

The Pprocess provides versatility

and flexibility, which can be implemented as a whole or step by step, and easy to be easily adapted

to local industrialy

conditions and requirements.

CONTACT

PERSON: Mr. Carlos Frías,

TÉCNICAS REUNIDAS, S.A., R&D Division

Calle Sierra Nevada,

16 - San Fernando de Henares - 28830 Madrid (SPAIN)

Phone: 34 91 6558780;

Fax: 34 91 6558789; E-mail: cfrias@tecnicasreunidas.es